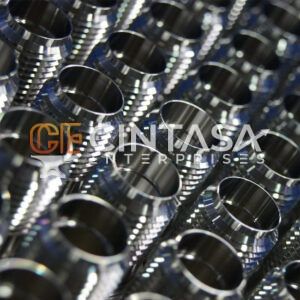

Machining

Cintasa Enterprises has establishment of a Precision Machining and Testing Center for Complex Parts. This sophisticated unit has been set up in Ludhiana and is dedicated to precision machining of forged and intricate components. Our unified Precision Tool Shop has sophisticated CNC equipment which consist of CNC Horizontal Lathes, Vertical Milling Centers that can perform 3 or 5 Axis operations and make parts up to 4 meters high and 8 meters long. Also in place are in-house CNC programming and modeling, design and fabrication of jigs and fixtures, and these are backed by a dedicated facility for inspection and testing.

Well-Equipped Machine Shop

Our machine shop is equipped with the latest machinery to handle all machining requirements with precision and efficiency:

- CNC Turning Machine: Our CNC turning machine ensures precise and consistent turning operations for complex geometries.

- CNC Vertical Milling: This machine provides high-precision milling capabilities for various components.

- HMC Machining: Our horizontal machining centers (HMC) offer efficient and accurate machining of large and complex parts.

- Convention Machines: These machines handle a wide range of conventional machining tasks, ensuring versatility and reliability in our production processes.

Common Facilities Available Nearby

To further support our operations, we have access to additional testing and research facilities in the vicinity:

- Direct Reading Spectrometer: For precise analysis of metal compositions.

- Universal Testing Machine: To measure the mechanical properties of materials, including tensile and compressive strength.

- Radiographic Testing: Available at nearby R&D centers, this facility helps detect internal flaws in castings.

- Ultrasonic Testing: Ensures the integrity of our castings by detecting internal defects using ultrasonic waves.

- Magnetic Particle Testing: This non-destructive testing method detects surface and near-surface defects in ferromagnetic materials.