Forging

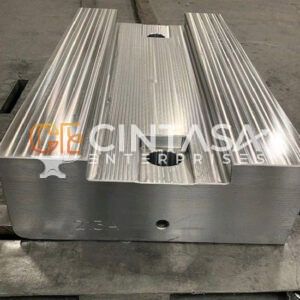

Welcome to Cintasa Enterprises: Leading the Way in Forging Excellence

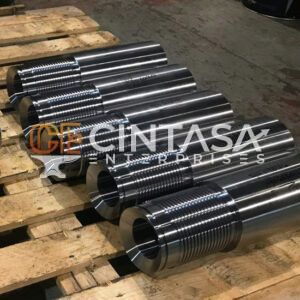

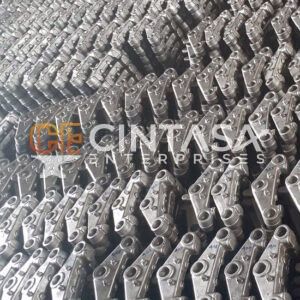

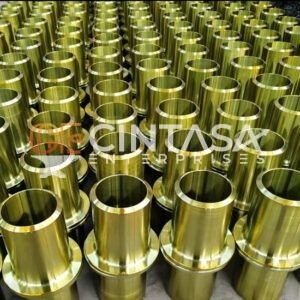

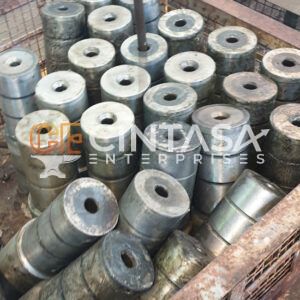

At Cintasa Enterprises, we specialize in high-quality forging services, leveraging state-of-the-art equipment and extensive expertise to meet the diverse needs of our clients. Our commitment to precision, flexibility, and stringent quality control ensures that we deliver superior forgings, catering to both low and high-volume requirements.

Advanced Forging Capabilities

Our forging operations are equipped with a range of hammers, from a 0.5-ton friction drop hammer to a 5.5-ton pneumatic hammer. This versatility allows us to produce forgings that range from as small as 100 grams to as large as 150 kilograms. We process nearly 2,500 tons of material annually, serving industries that require small to medium batch quantities in various carbon, high alloy, and stainless steels.

Flexible Manufacturing Approach

At Cintasa Enterprises, we pride ourselves on our unique flexibility in manufacturing quantities. Whether you need low-volume spare parts or large-scale OEM requirements in the thousands, we are equipped to meet your needs. Our billets are heated in oil-fired or electric furnaces with precise temperature control to minimize scale formation and overheating, thus preserving the metallurgical properties of the final product.

Rigorous Quality Control

We implement in-process inspections at all stages of production and conduct 100% visual inspections for defects after forging. Accepted forgings are then heat-treated to ensure optimal mechanical properties, adhering to the highest standards of quality and reliability.

Comprehensive Post-Forging Operations

Our in-house heat treatment services allow us to maintain stringent control over the heat-treating process. Our facilities include batch furnaces (both oil-fired and electric), continuous electric heating furnaces, and solution treatment units. We offer a variety of heat treatment processes, including:

- Annealing

- Normalizing

- Hardening

- Tempering

- Iso-thermal Annealing

- Solution Treatment

Each process is closely monitored with temperature recorders to ensure uniform properties. We support these treatments with thorough evaluations of metallurgical properties through representative test pieces.

Accredited Testing and Calibration

Our facilitation center is approved by the National Accreditation Board for Testing and Calibration Laboratories (NABL). This ensures that our testing and calibration processes meet the highest standards of accuracy and reliability. Our comprehensive testing capabilities include:

- Metallurgical Property Evaluation

- Mechanical Testing

- Chemical Analysis

With these facilities, we guarantee that every forging meets the specified requirements and performs reliably in its intended application.

Serving Diverse Industries

Cintasa Enterprises serves a wide range of industries, each with unique demands for high-quality forged components. Our flexible approach and comprehensive capabilities allow us to meet the specific needs of sectors such as:

- Automotive

- Defence

- Railways.

- Aerospace

- Oil and Gas

- Construction

- General Engineering

Commitment to Customer Satisfaction

At Cintasa Enterprises, customer satisfaction is at the heart of everything we do. Our team is dedicated to understanding your specific needs and providing tailored solutions that drive efficiency and innovation. We offer competitive rates without compromising on quality, ensuring that you receive the best value for your investment.

Contact Us

We invite you to reach out with your forging requirements. Our team is ready to provide you with detailed quotes and discuss how we can meet your specific needs. Experience the Cintasa Enterprises difference – where quality, precision, and customer satisfaction are our top priorities.

Thank you for considering Cintasa Enterprises for your forging needs. We look forward to partnering with you and contributing to your success with our top-tier forging services.